The factory floor is no longer a scene from a bygone era, filled with clanging machinery and tireless workers. Today, a new era of manufacturing has dawned, driven by the relentless march of technology. Robotics has transformed the way we produce goods, ushering in an age of automation, efficiency, and precision.

This isn’t just about replacing human workers with machines. It’s about creating a smarter, more collaborative manufacturing environment where humans and robots work in tandem to achieve incredible feats of production. But how has robotics changed manufacturing? Let’s delve into the fascinating world of industrial robots and explore their impact on this critical sector.

History of Robotics in Manufacturing

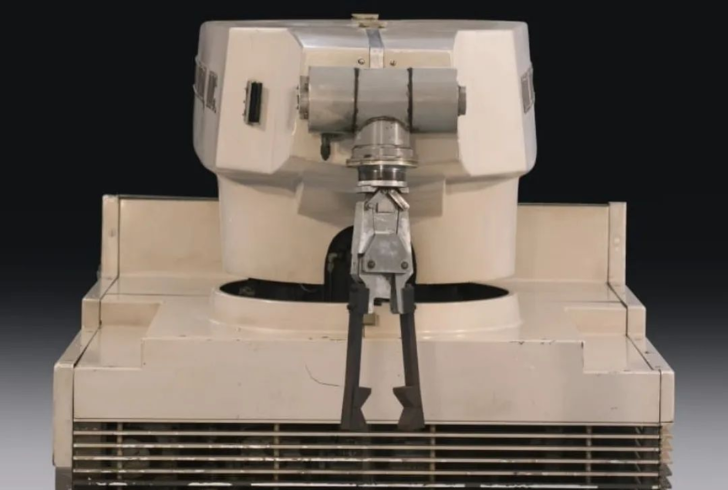

Instagram | plymoventindustrialproducts | In 1961, a pivotal milestone occurred with the introduction of Unimate, the inaugural industrial robot.

The story of robotics in manufacturing stretches back to the 1950s, a time when the concept of robots seemed like science fiction. Then came 1961, a pivotal year that witnessed the birth of Unimate, the first industrial robot. This groundbreaking invention revolutionized assembly lines by automating tasks that were once considered too dangerous or monotonous for human workers.

Fast forward to today, and industrial robots have come a long way from their simple pick-and-place origins. Advancements in artificial intelligence (AI), sensor technology, and the Internet of Things (IoT) have empowered them to tackle complex tasks like welding, painting, and intricate assembly with remarkable precision.

How Has Robotics Changed Manufacturing Efficiency?

Robotics has significantly enhanced productivity, efficiency, and safety within manufacturing. By operating tirelessly 24/7, robots accelerate production rates and minimize downtime, ensuring consistent product quality while reducing human error. Moreover, they have enabled the automation of hazardous tasks, thereby improving workplace safety conditions.

The Advantages of Embracing Robotics

Freepik | Lifestylememory | By handling tasks such as welding and heavy lifting, robots significantly reduce workplace accidents and injuries.

There’s a compelling reason why manufacturers are increasingly turning to robotics. Here are some of the key advantages this technology offers:

-

Enhanced Efficiency and Productivity – As mentioned earlier, robots can churn out products at a much faster rate than human workers, leading to significant gains in productivity.

-

Improved Quality Control – Repetitive tasks and human error become a thing of the past with robotic automation. Robots deliver consistent quality and precision in every step of the manufacturing process.

-

Greater Flexibility – Modern robots are no longer one-trick ponies. They can be easily reprogrammed to adapt to new tasks or production changes, offering manufacturers greater flexibility in their operations.

-

A Safer Work Environment – By taking over dangerous tasks like welding and heavy lifting, robots play a crucial role in reducing workplace accidents and injuries.

Challenges on the Road to Automation

While the benefits of robotics are undeniable, integrating these machines into existing workflows presents some challenges:

-

The Price Tag of Progress – The upfront cost of acquiring and installing robots can be substantial, particularly for smaller manufacturers. However, as robotics technology matures, the cost is expected to decrease, making it more accessible.

-

The Need for Specialized Skills – Robots require skilled personnel for programming, operation, and maintenance. This necessitates training programs to equip the workforce with the necessary skills to work alongside these robotic co-workers.

-

Integration Hurdles – Seamlessly integrating robots into existing manufacturing processes can be complex. Careful planning and adaptation of existing infrastructure are often necessary.

Future Trends in Robotics and Manufacturing

Freepik | AI and machine learning enhance robots’ autonomy and decision-making.

Looking forward, the future of robotics in manufacturing is influenced by several emerging trends. Advanced AI and Machine Learning are enhancing robots’ autonomy and decision-making abilities. Collaborative Robots (Cobots) are designed to collaborate with human operators, improving teamwork and operational flexibility.

Additionally, as robotics technology becomes more affordable, its adoption is anticipated to increase across SMEs and larger manufacturing enterprises. These trends promise to further revolutionize the manufacturing industry, making processes more efficient and adaptable to changing demands.

The evolution of robotics in manufacturing signifies a transformative shift towards automated, efficient, and safer production processes. This shift exemplifies how robotics has changed manufacturing, making it more streamlined and cost-effective. While challenges persist, ongoing technological advancements and the recognized benefits of robotics herald a future where these systems play a pivotal role in modern industry.